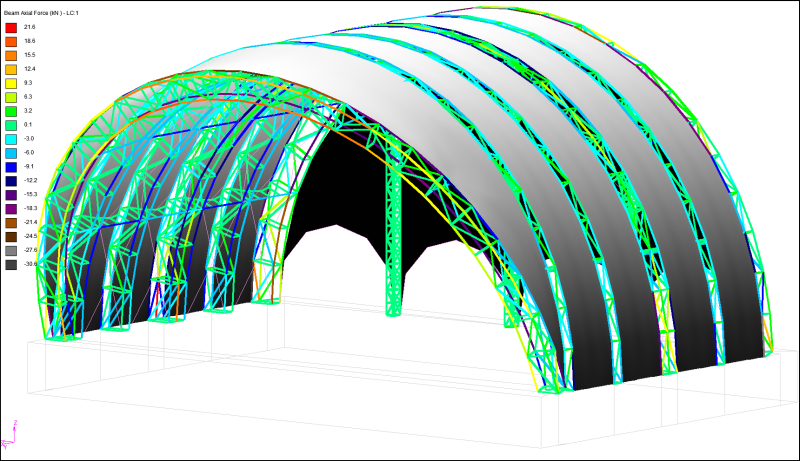

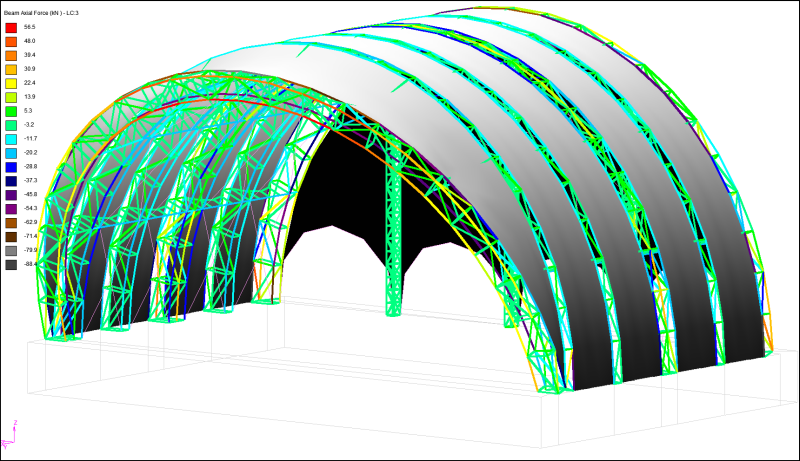

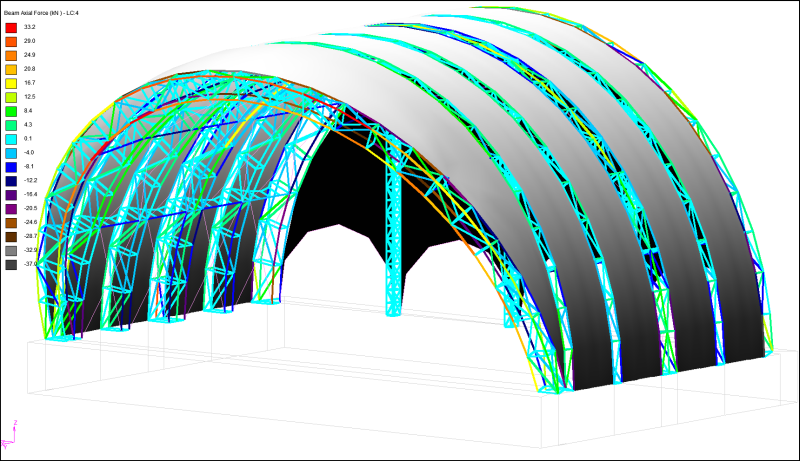

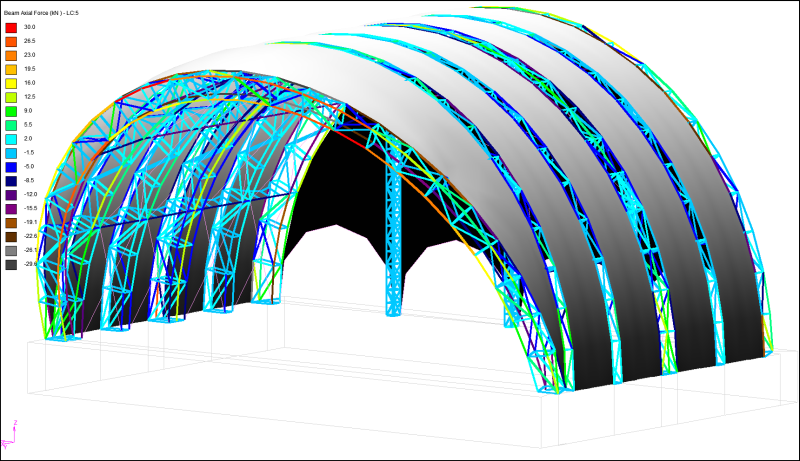

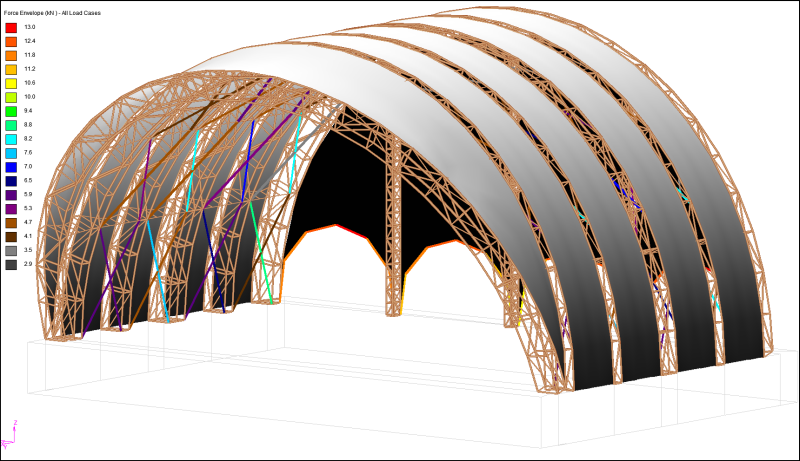

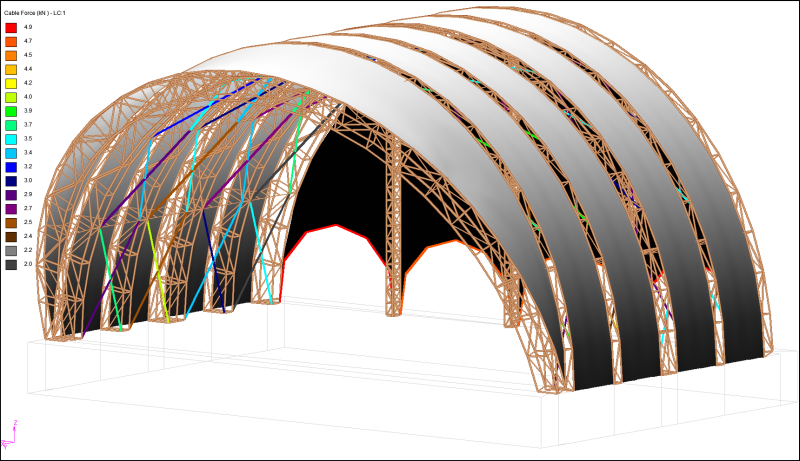

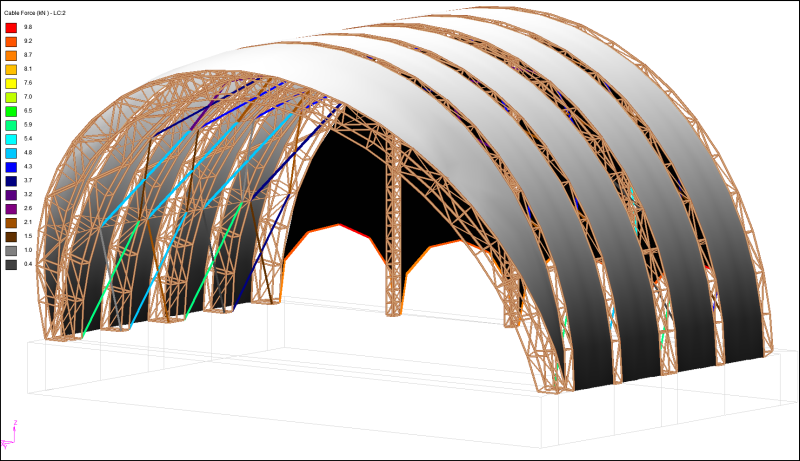

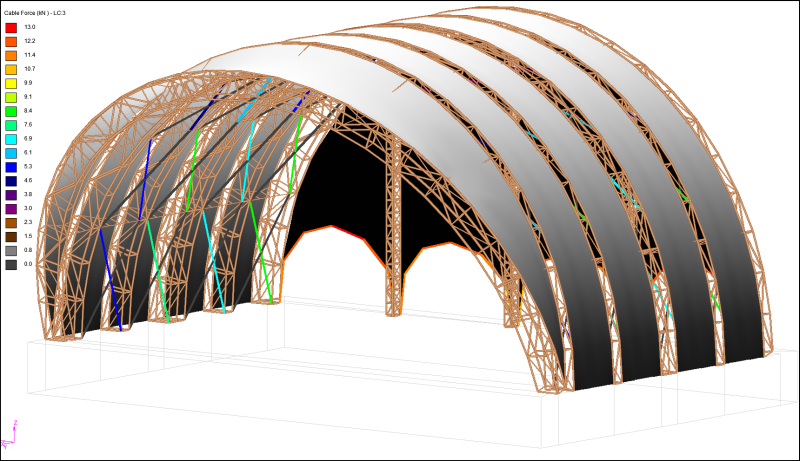

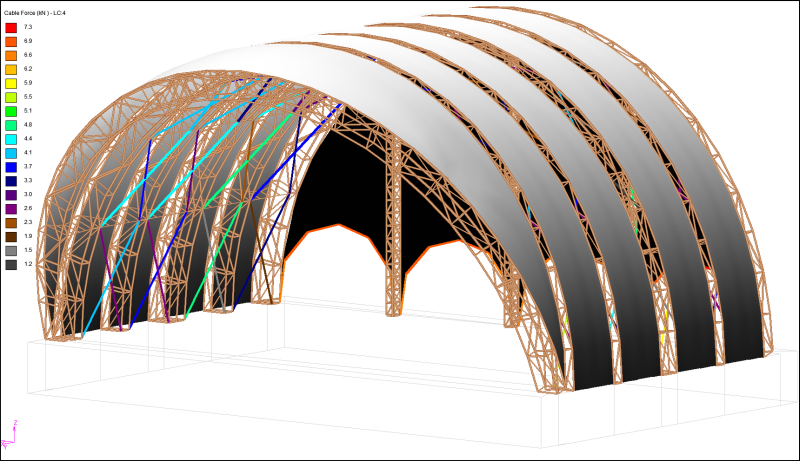

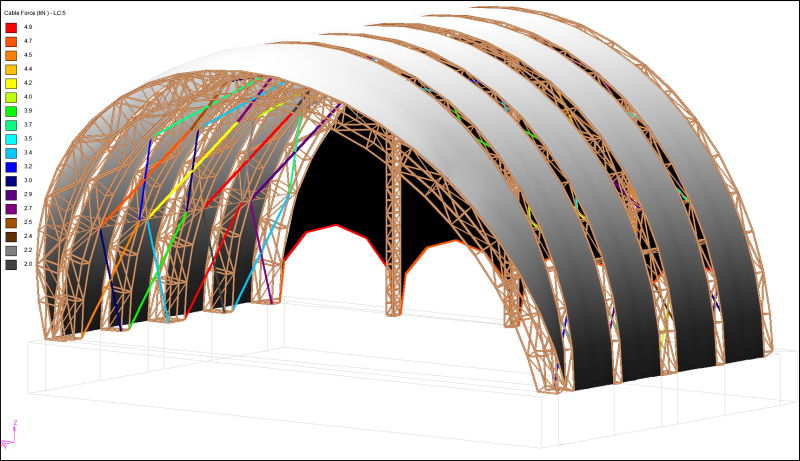

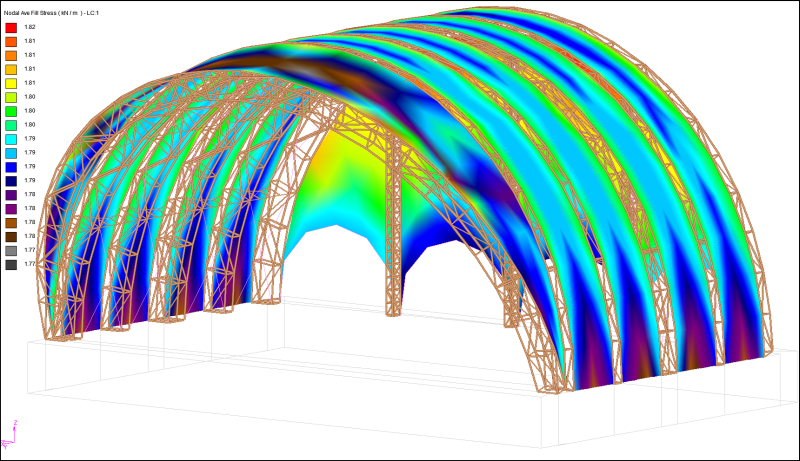

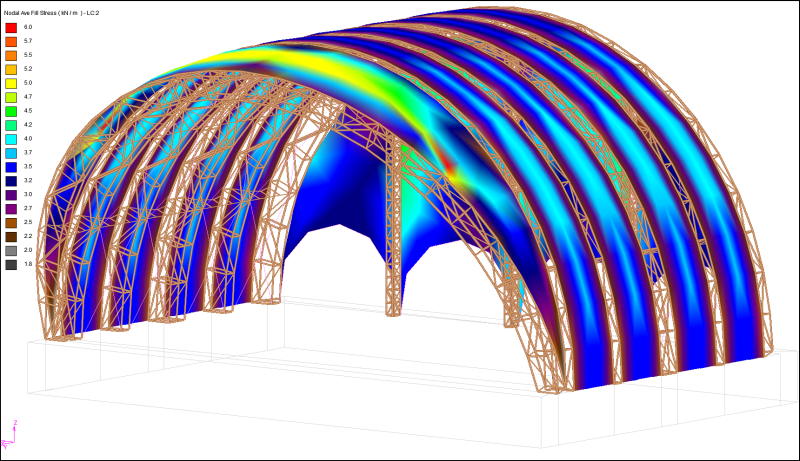

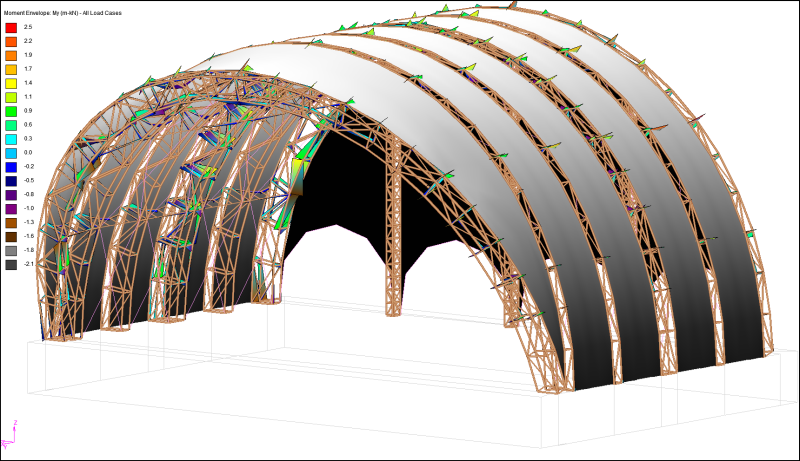

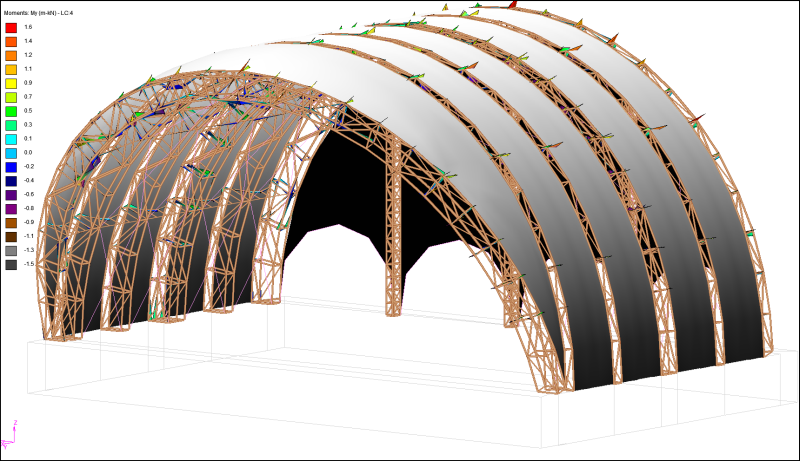

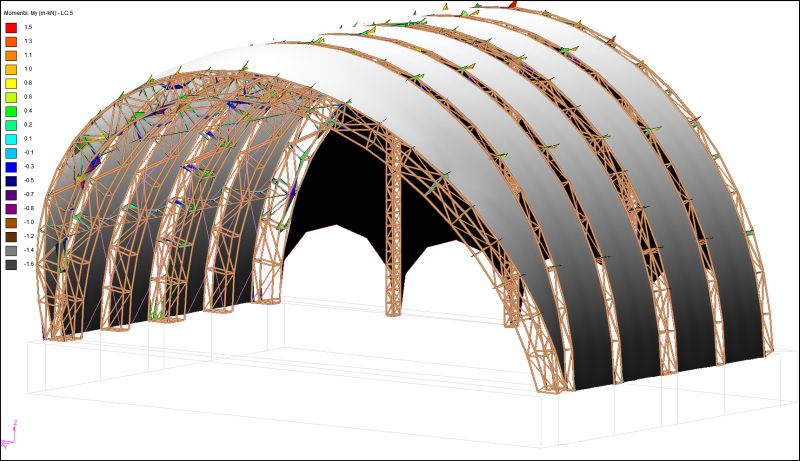

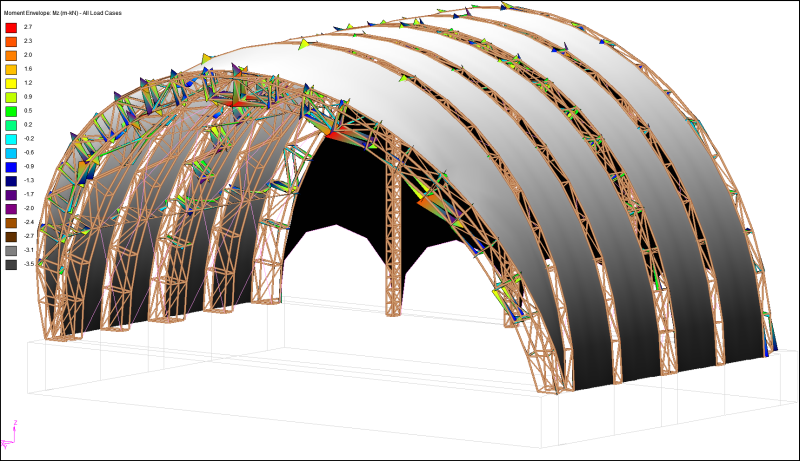

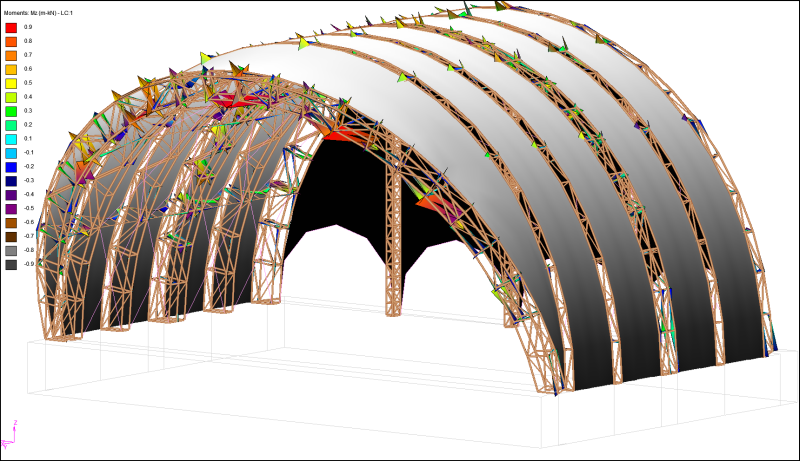

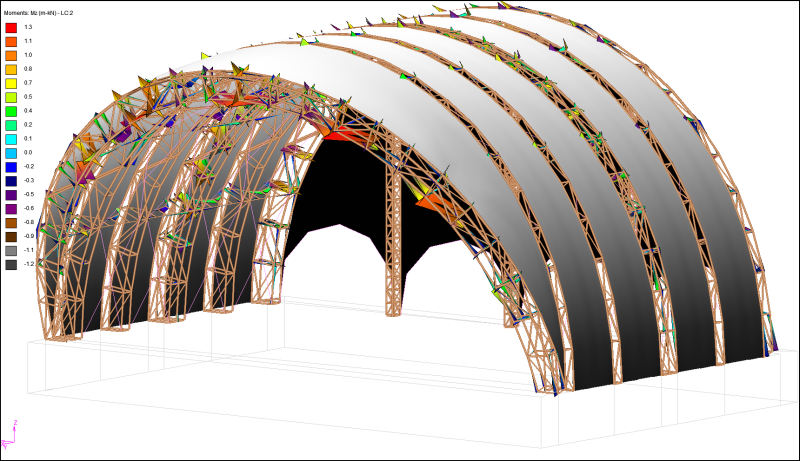

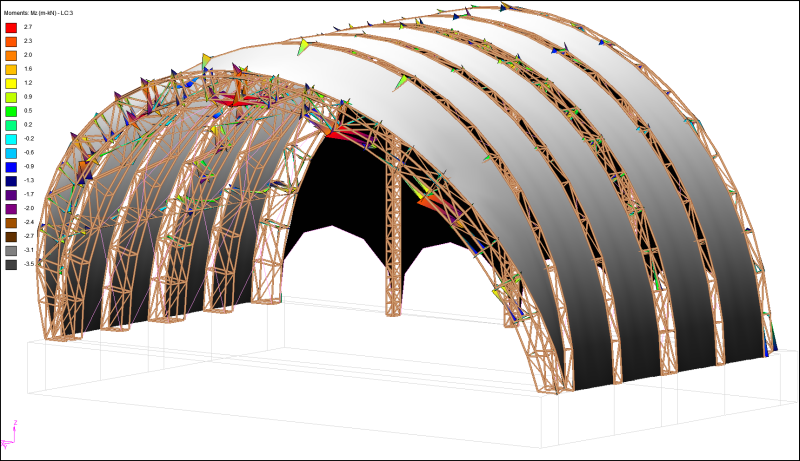

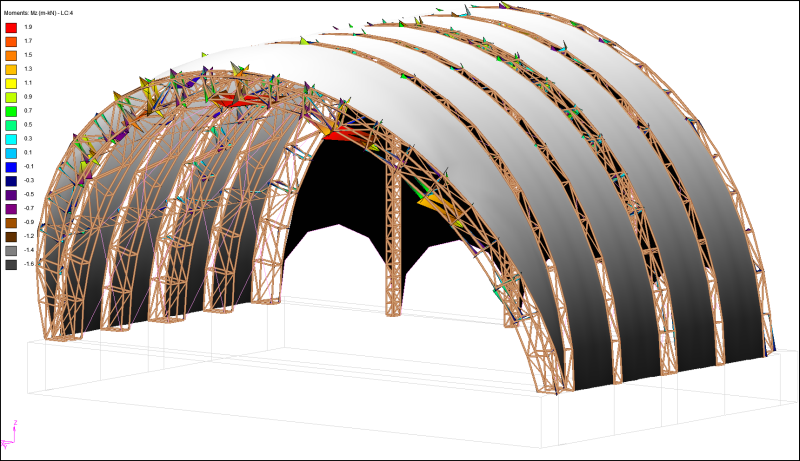

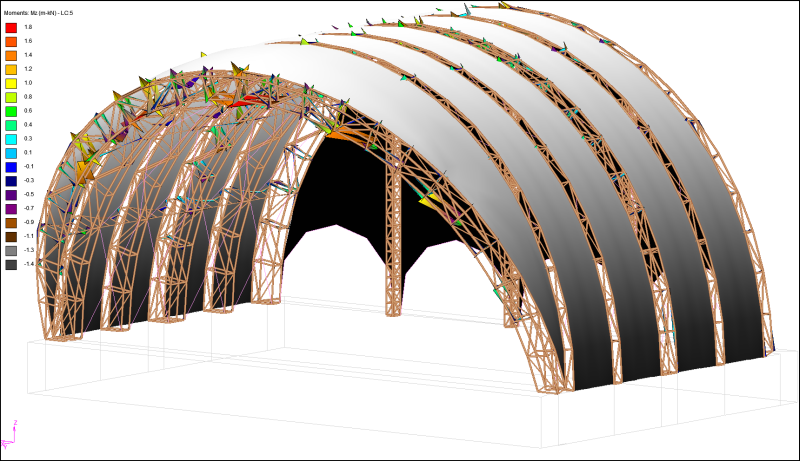

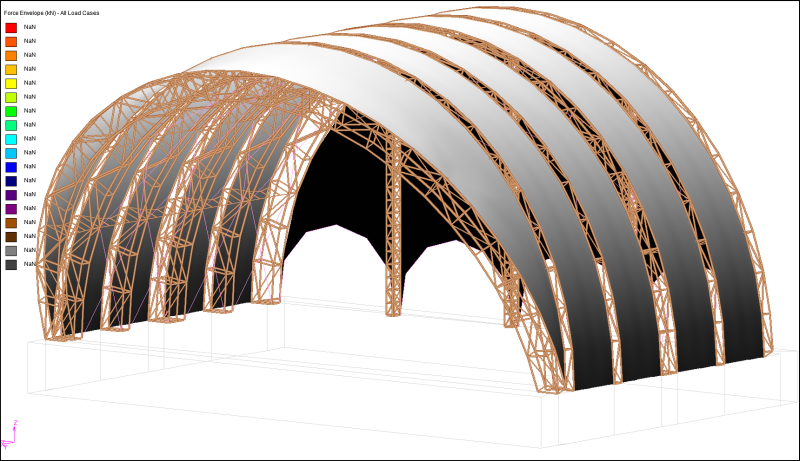

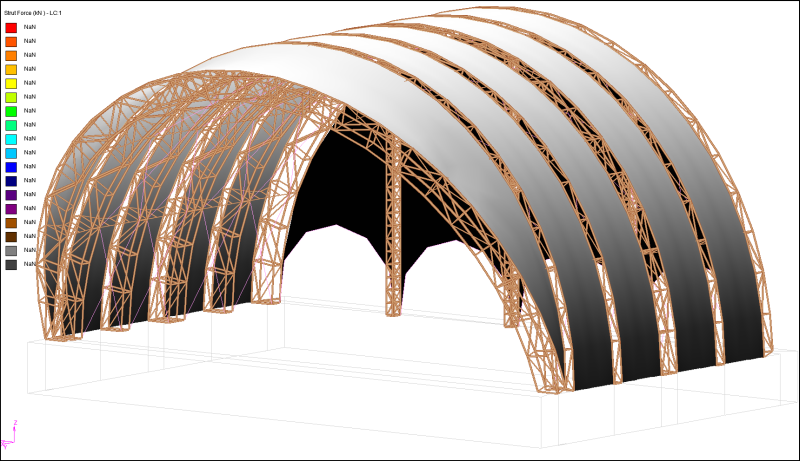

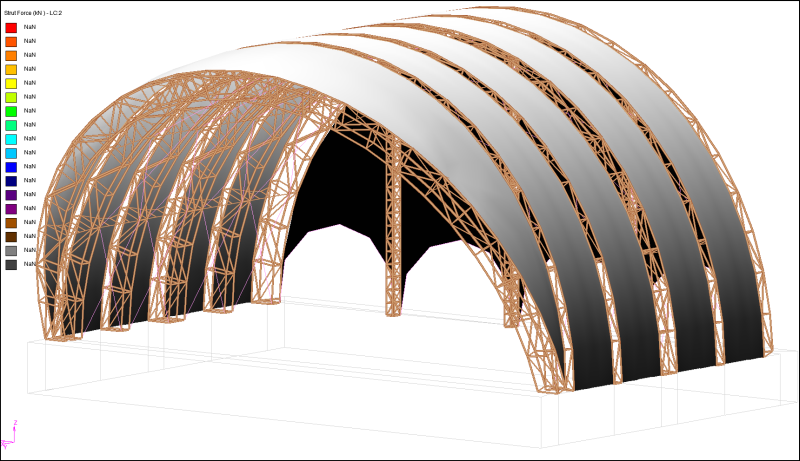

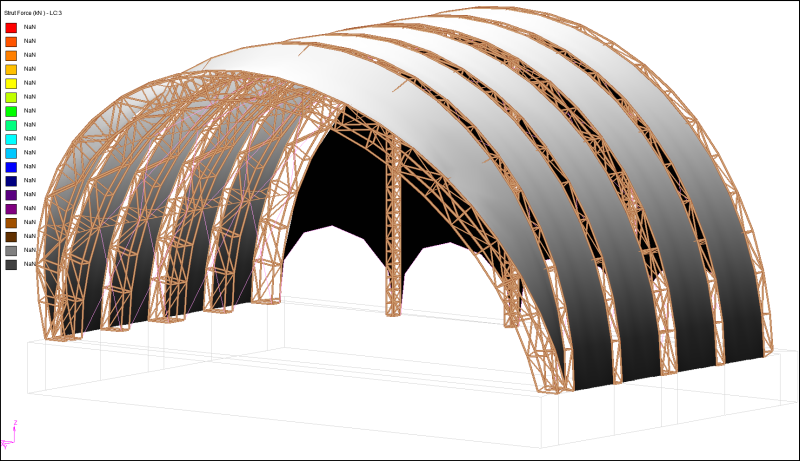

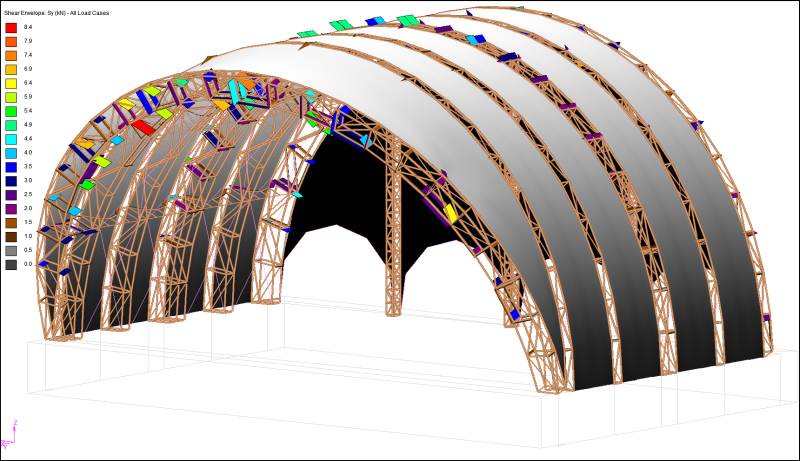

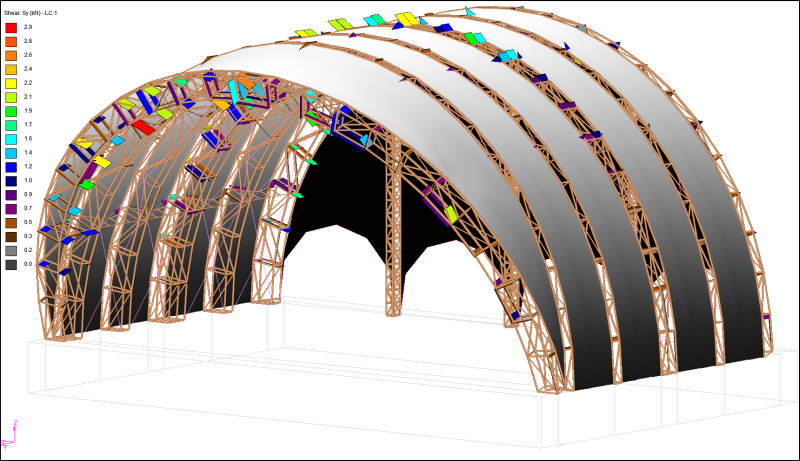

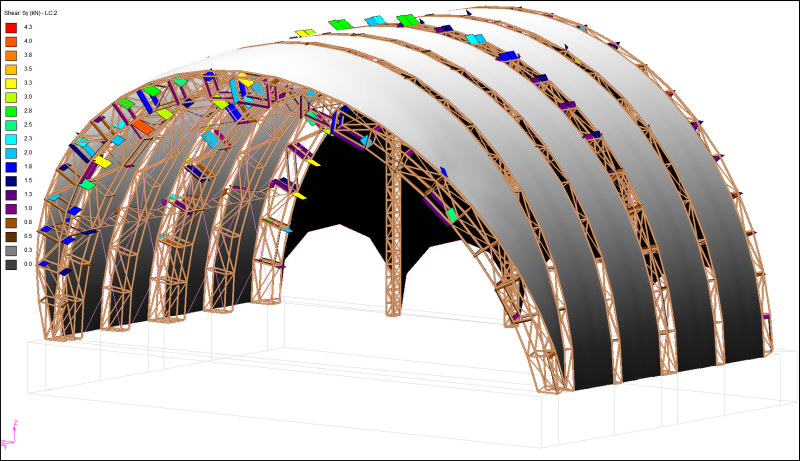

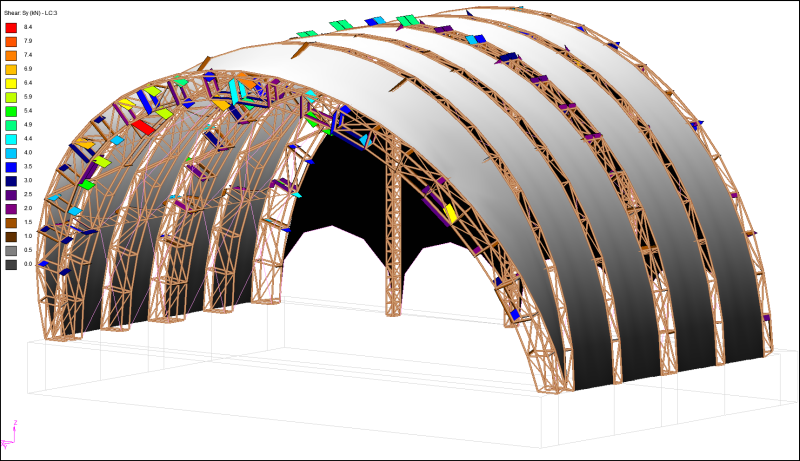

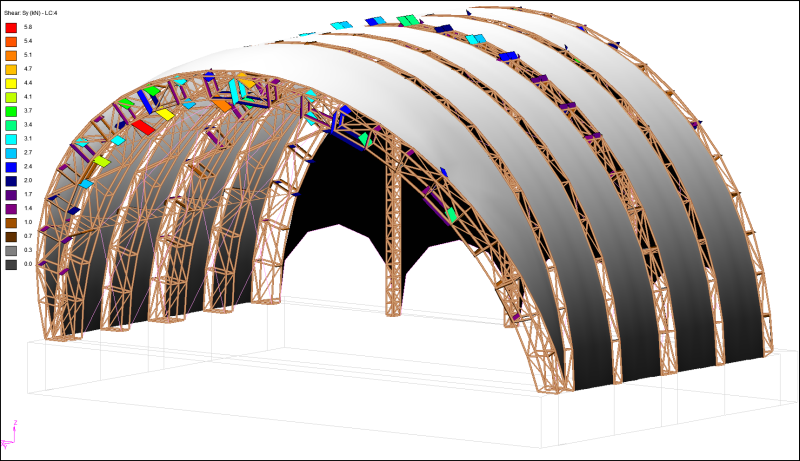

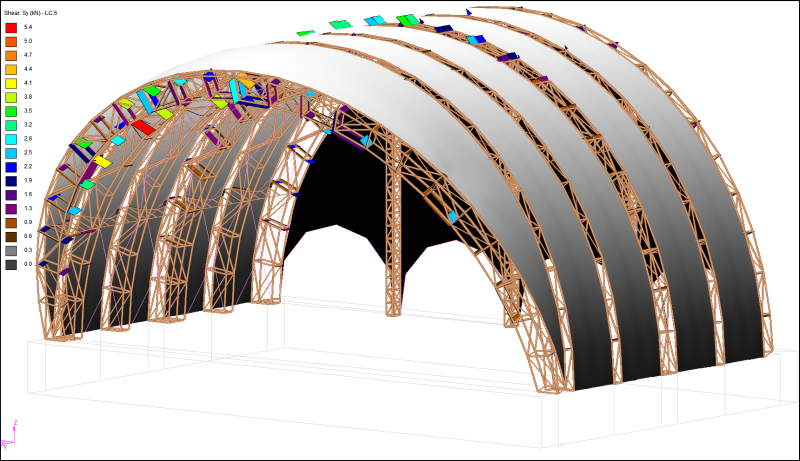

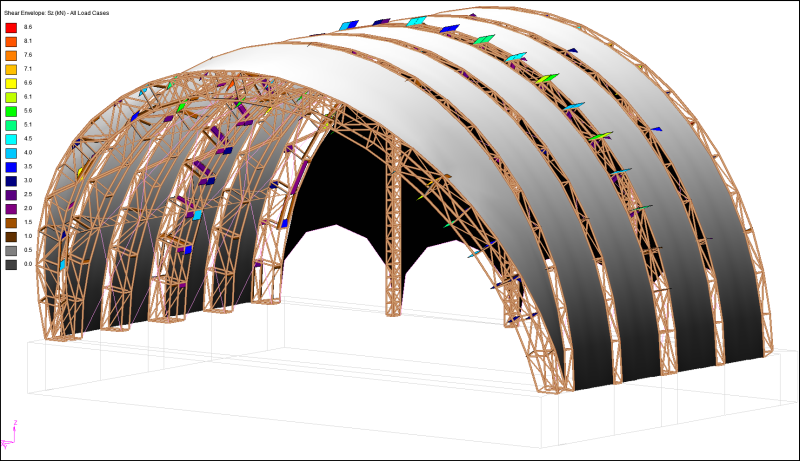

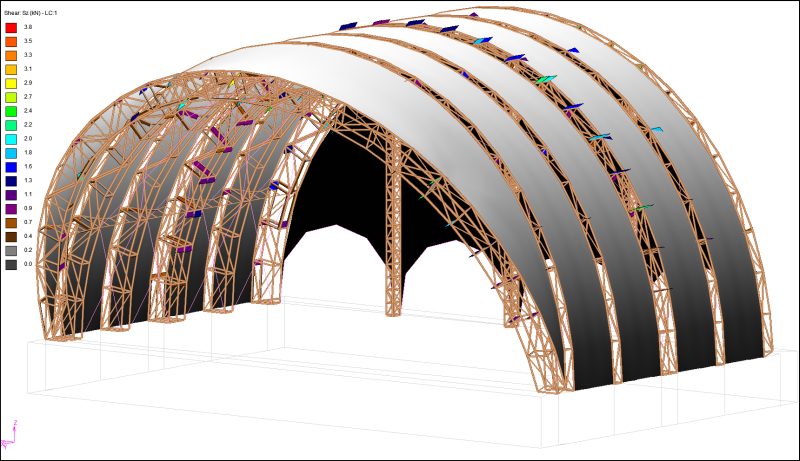

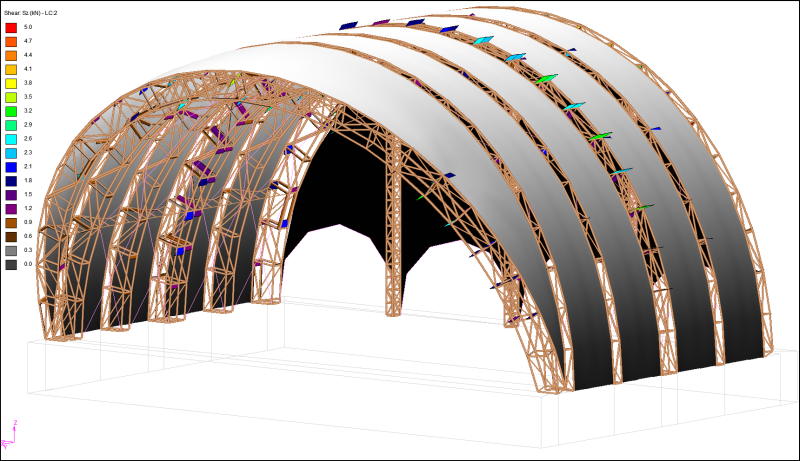

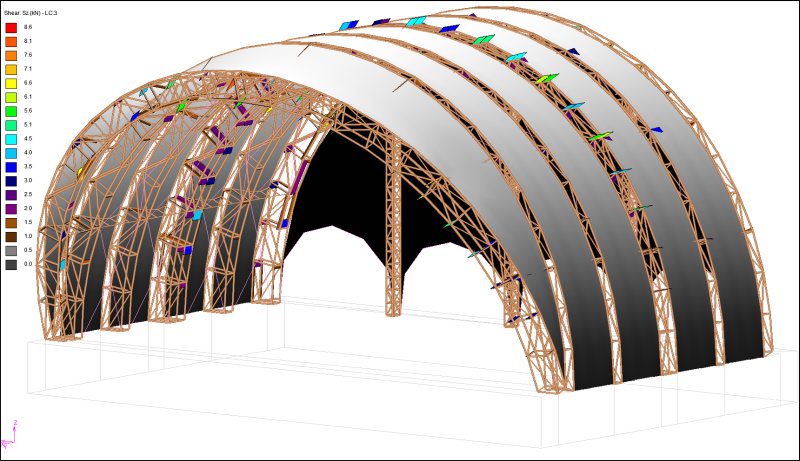

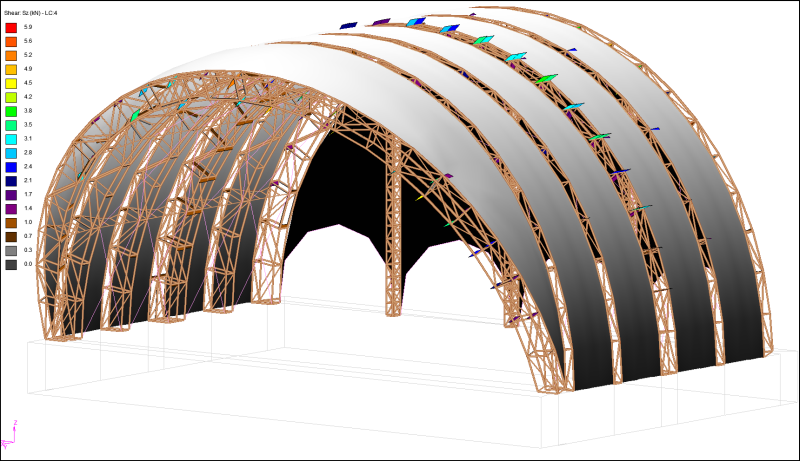

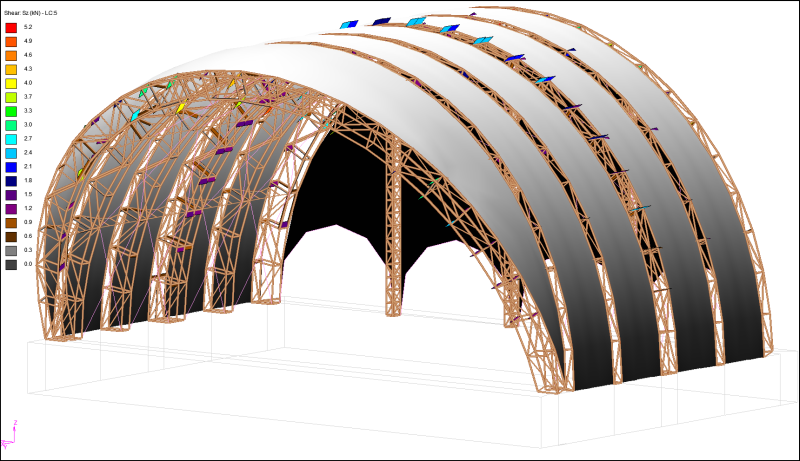

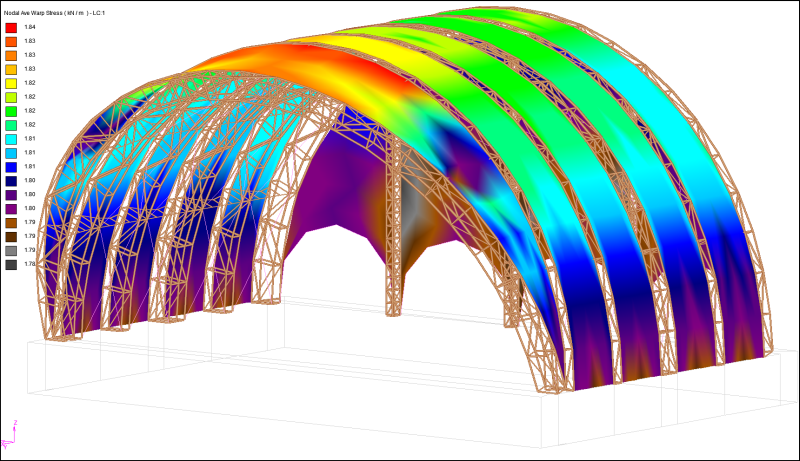

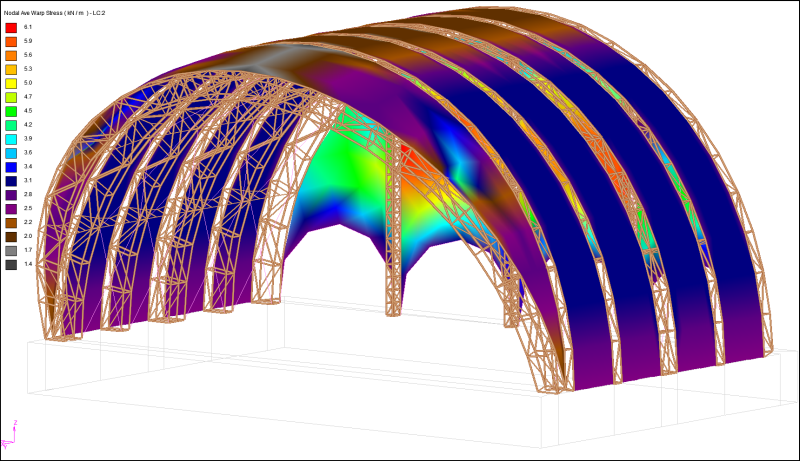

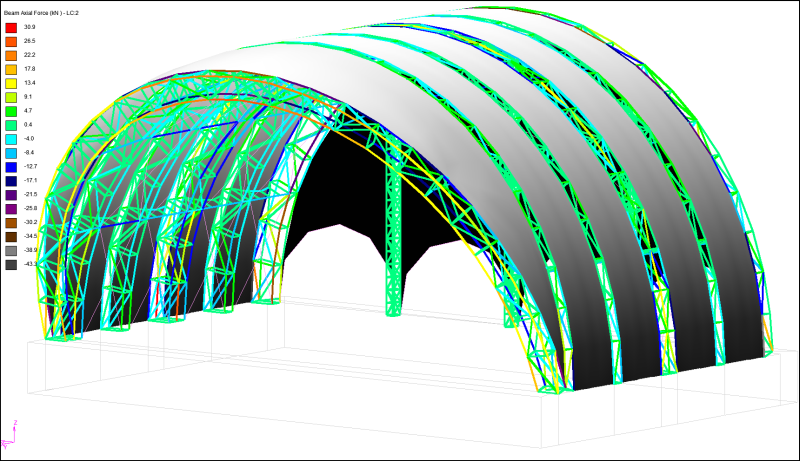

Special Structures Lab use the NDN Membrane or Easy NT suite of analysis tools.

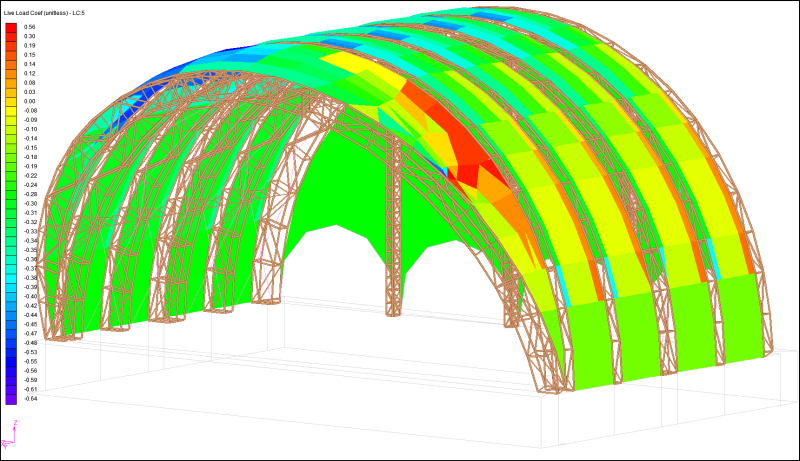

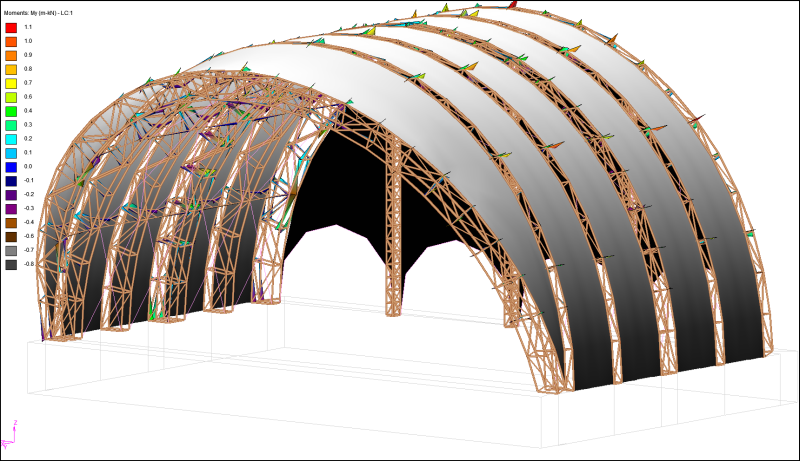

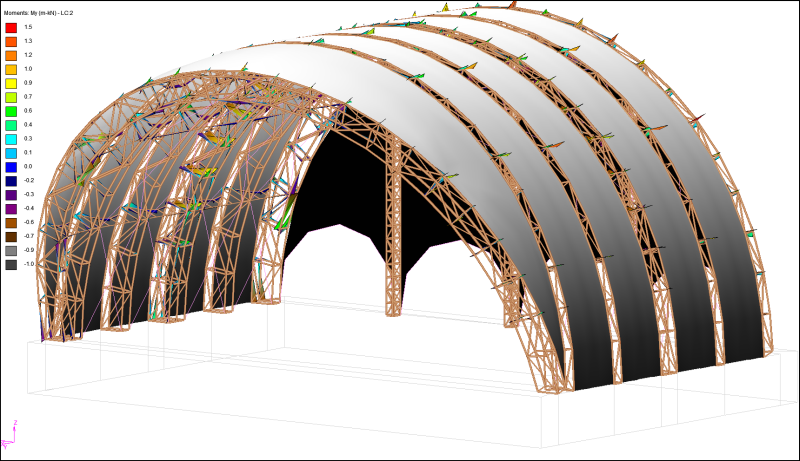

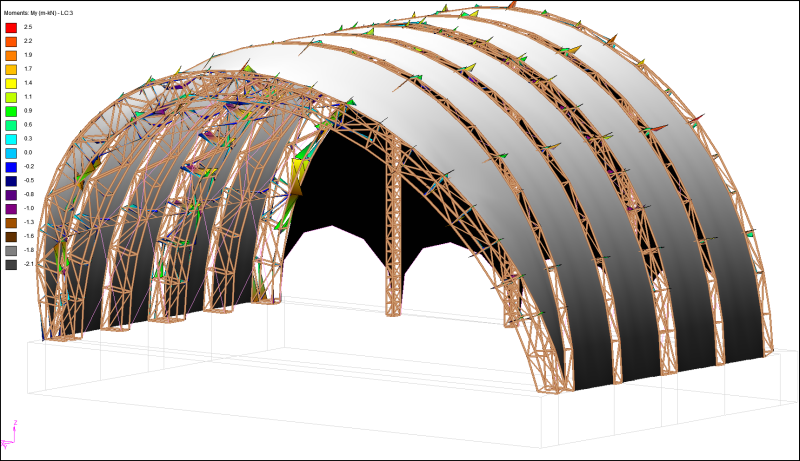

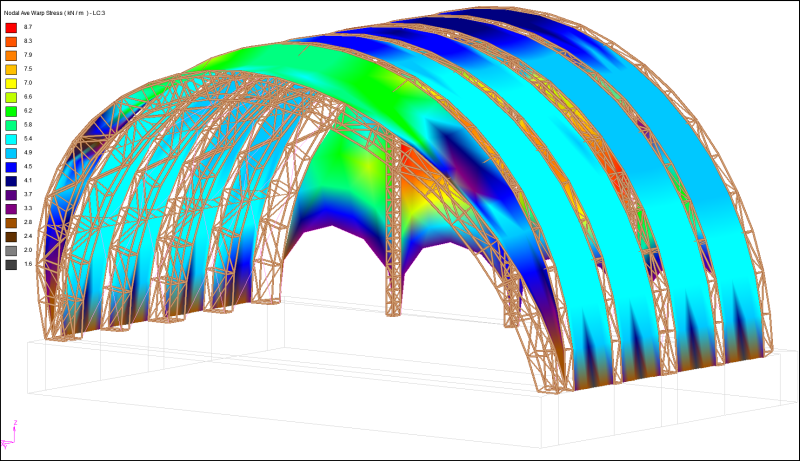

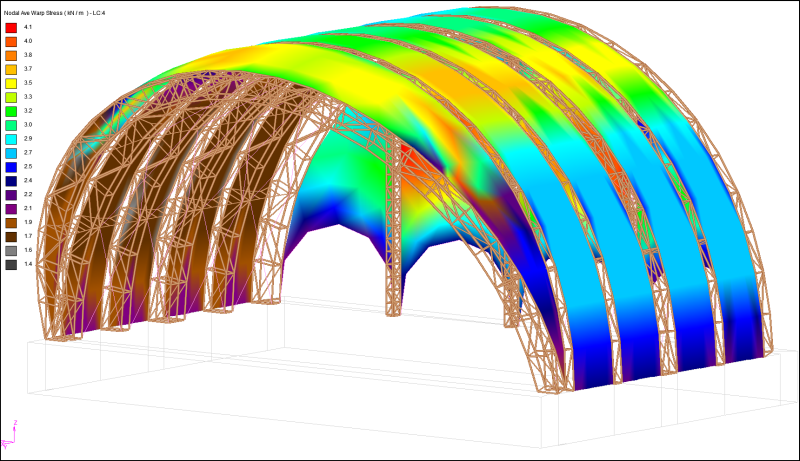

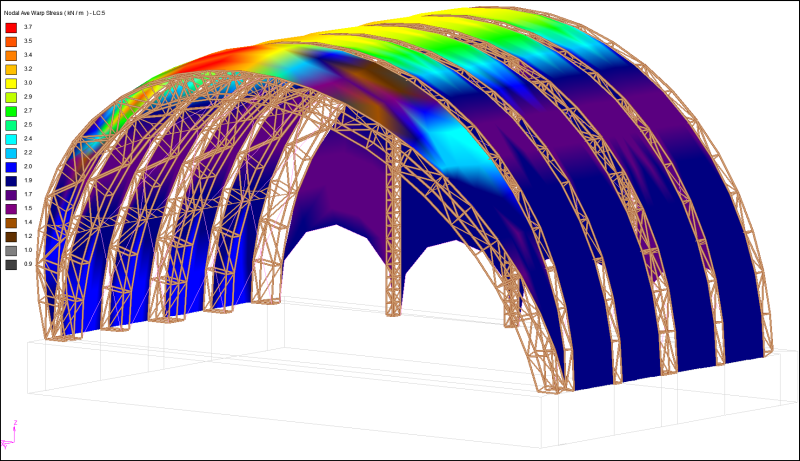

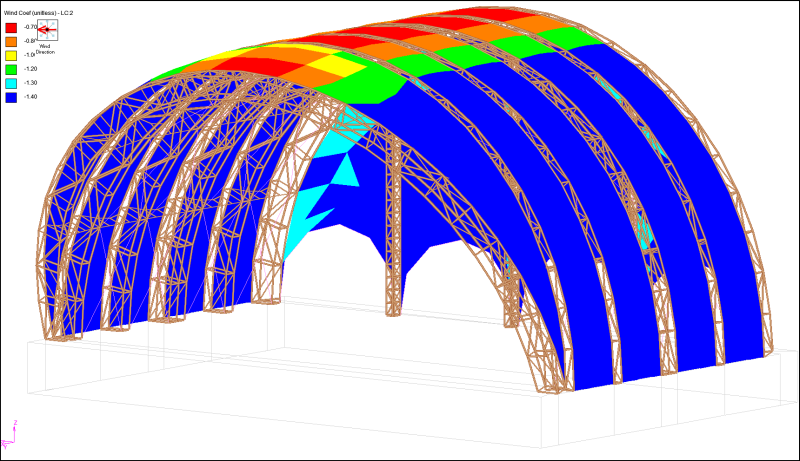

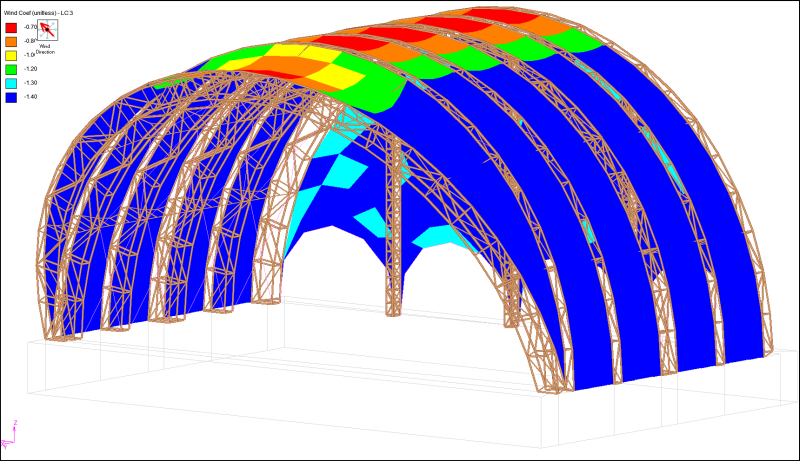

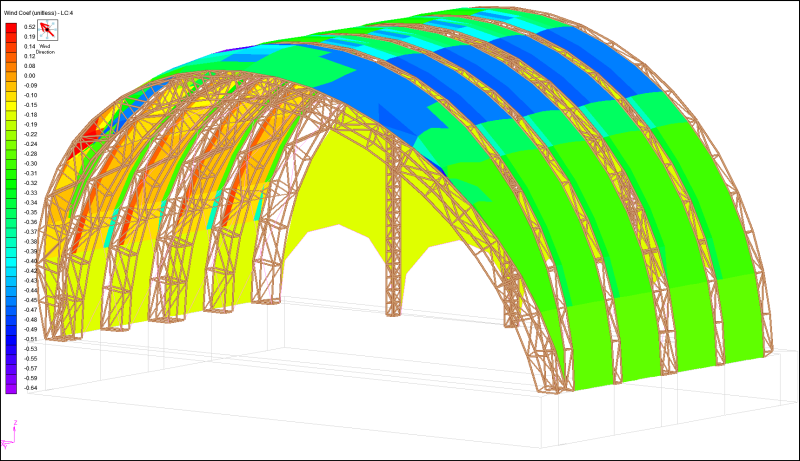

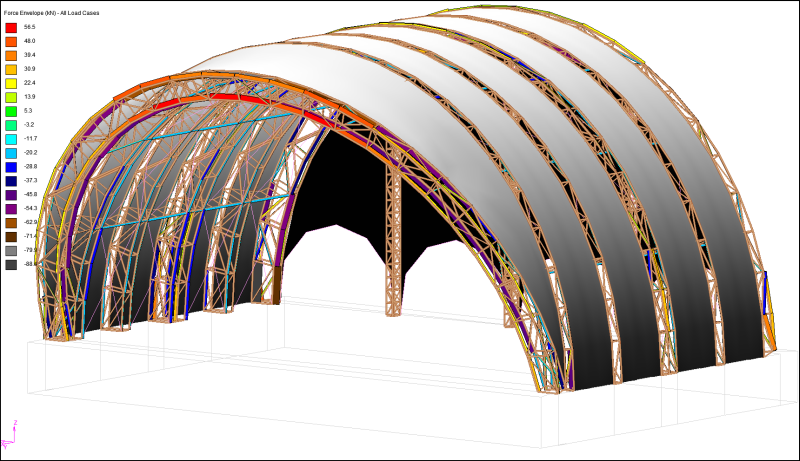

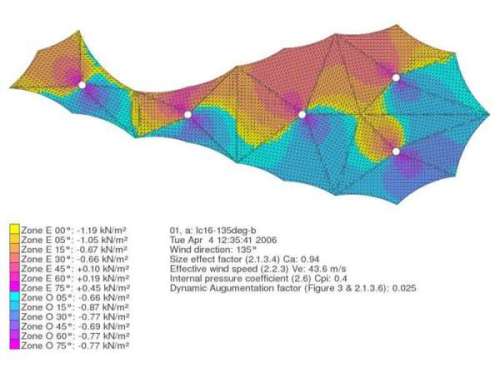

Typical membrane structures defy classical analysis. Modern engineers use sophisticated software tools to generate virtual models which can represent the real world project. Every part of the virtual model can have properties simulated to represent forces and structural components in software. The model can then have surface pressures defined from projected wind patterns and assigned. There are two main methods used to determine equilibrium shape in the commercial world of membrane roof manufacture. These are the 'dynamic relaxation' method and the 'force density method. SSL use the force density method with Easy NT.

simulated to represent forces and structural components in software. The model can then have surface pressures defined from projected wind patterns and assigned. There are two main methods used to determine equilibrium shape in the commercial world of membrane roof manufacture. These are the 'dynamic relaxation' method and the 'force density method. SSL use the force density method with Easy NT.

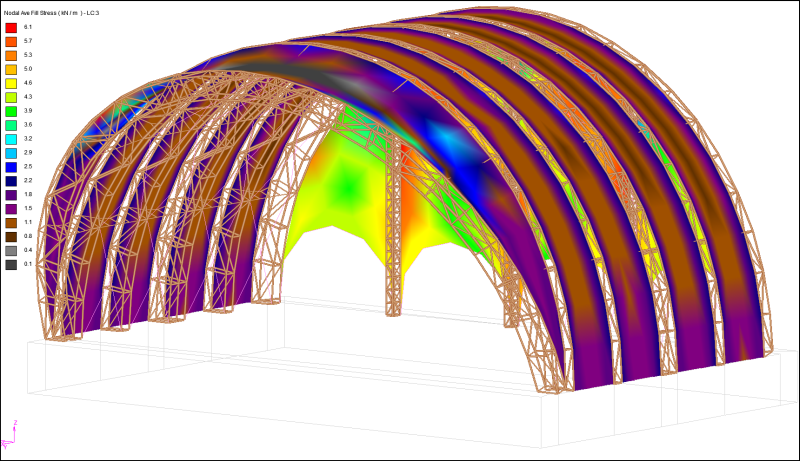

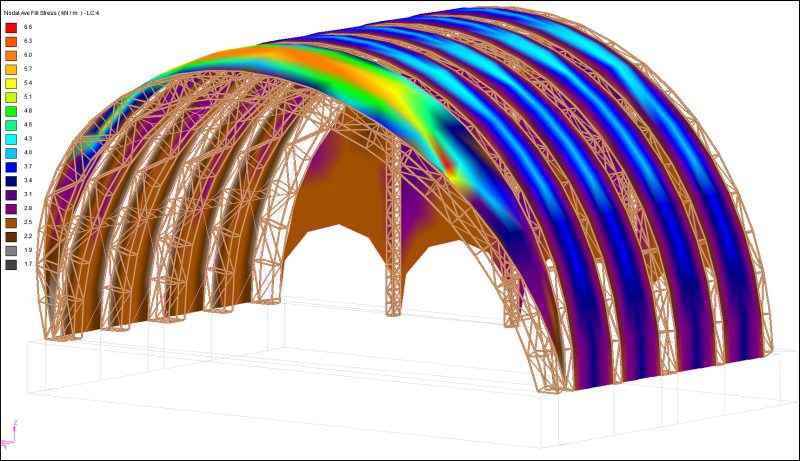

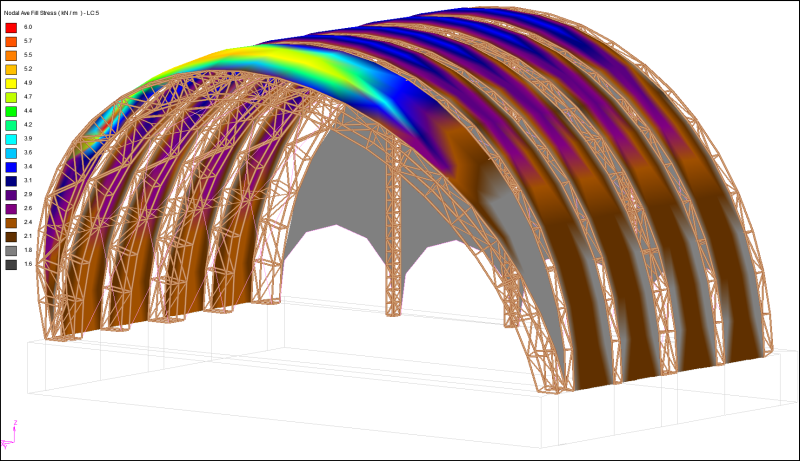

Membrane surfaces exhibit both geometric non-linearity due to large deflections in addition to fabric non-linearity. Non linear analysis is used where displacement may not equal the applied force depending on scale. The surface is normally represented as a mesh. The representative mesh is analysed using non linear FEA (finite element analysis) to determine the forces in the membrane, the perimeter cables and the loads to the main supporting elements. The elements are usually masts and cables, but beams, concrete members or even timber can provide support.